Fast Company

Dairy Waste Processing

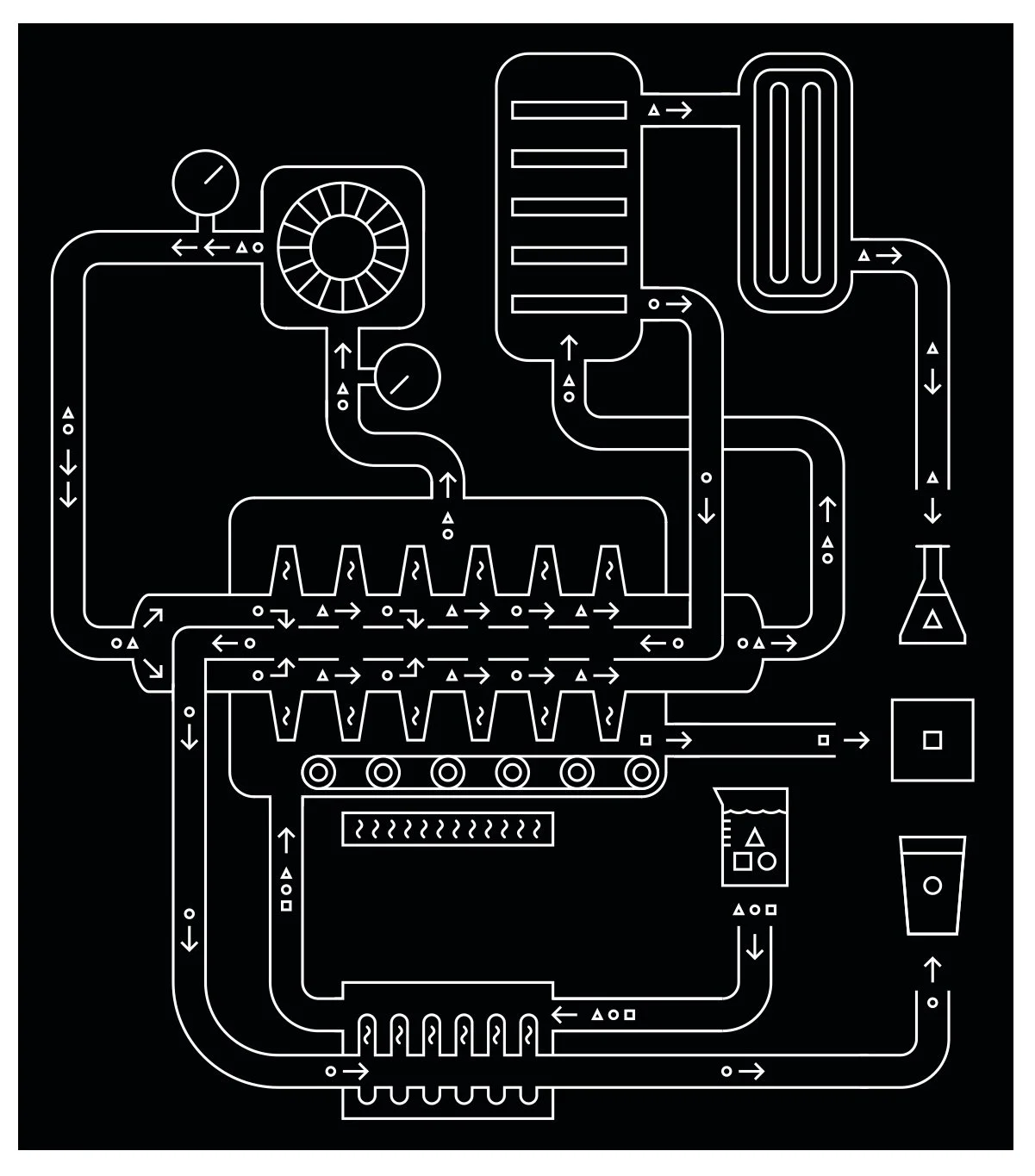

This diagram shows a new process that converts dairy cow waste into two kinds of fertilizer and clean water.

Here are what the symbols represent:

Triangle: liquid fertilizer

Circle: water

Square: dry fertilizer

The process starts with the beaker in the lower right. At this point all three of the end products are mixed together in a slurry.

The slurry enters the system and is preheated by the outgoing hot water.

It then enters the main heating chamber in the central part of the illustration. The heat drys the solids (squares) which proceed along a conveyor belt and exit the system.

The remaining liquid vapor (triangles and circles) exits the top of the heating chamber and moves through a compressor.

The high pressure vapor then moves back through the heating chamber in an enclosed, finned tube, releasing heat as the vapor expands.

Here some of the water vapor leaves the system and preheats the incoming slurry on its way out.

The remaining vapor moves to a distiller in the upper right part of the graphic. Here the it is separated into clean water and liquid fertilizer.

The water vapor passes back through the main heating chamber, releasing its heat, condensing into liquid, and exiting the system.

The fertilizer vapor runs through condenser and exits the system as liquid fertilizer.